Selecting an SMD quartz crystal is not a mechanical decision only. Package size directly affects ESR, startup margin, and layout sensitivity, which can lead to slow start, intermittent oscillation, or frequency drift if the crystal is mismatched to the oscillator. This guide explains how to choose between 2016, 3215, and 3225 packages for two common use cases: MCU clock crystals (MHz) and RTC crystals (32.768 kHz).

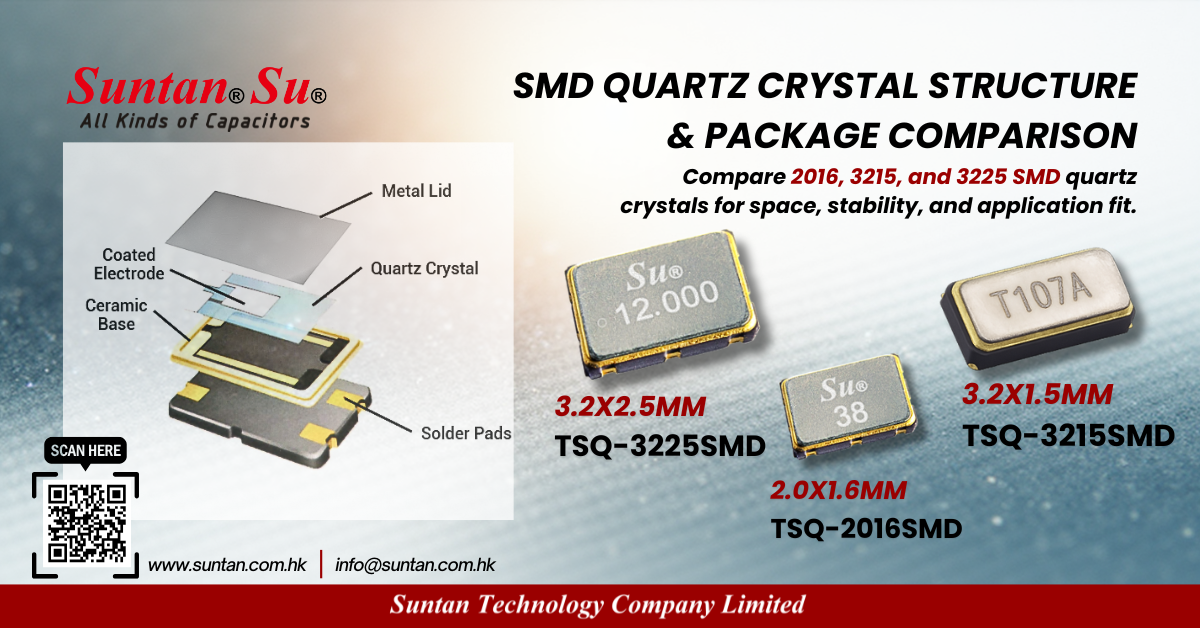

Reference products used in this article: TSQ-2016SMD, TSQ-3215SMD, TSQ-3225SMD.

1. Start with the oscillator type: MCU clock vs RTC

The first decision is not size, it is application class. MCU clocks typically use AT-cut crystals in the MHz range (fundamental mode), while RTC circuits use 32.768 kHz tuning-fork crystals optimized for ultra-low power. These two crystal structures behave differently in terms of motional parameters and drive level requirements, so they are not interchangeable.

Practical implication: if the design is an RTC domain (LSE), prioritize CL matching and low-power stability. If the design is an MCU main clock (HSE), prioritize startup margin, ESR headroom, and layout robustness.

2. Why package size affects ESR and startup margin

Smaller packages generally reduce mechanical volume and can increase effective resistance and sensitivity to PCB parasitics. In practice, moving from 3225 to 2016 often reduces board footprint but can tighten oscillator margin, especially with low-drive oscillator circuits. If the MCU datasheet specifies a maximum crystal ESR or a limited drive capability, the safer choice is typically a package with more margin, provided space allows.

For RTC 32.768 kHz tuning-fork crystals, the key risks are different: incorrect load capacitance (CL) setting, overdrive, and placement noise coupling. Many RTC failures look like “time drift” but originate from mismatched CL or noisy layout.

3. 2016 vs 3215 vs 3225 comparison table (engineering view)

| Package | Typical Frequency | Crystal Type | Best Fit | Main Design Risk |

|---|---|---|---|---|

| 2016 (2.0 × 1.6 mm) | 20–54 MHz | AT-cut (MCU clock) | Compact MCU and wireless modules where PCB area is limited (TSQ-2016SMD) | Tighter startup margin and higher sensitivity to layout parasitics. Validate ESR requirement and oscillator drive capability. |

| 3215 (3.2 × 1.5 mm) | 32.768 kHz | Tuning fork (RTC) | RTC timekeeping and ultra-low power standby (TSQ-3215SMD) | Incorrect CL setting and noise coupling near the RTC pins. Ensure the PCB and capacitor values match the specified CL. |

| 3225 (3.2 × 2.5 mm) | 12–54 MHz | AT-cut (MCU clock) | Industrial control, communication modules, designs prioritizing stability (TSQ-3225SMD) | Usually lowest risk for startup among these three sizes, but still requires CL and layout compliance with the MCU datasheet. |

4. A practical selection workflow engineers can apply

A reliable selection sequence is:

Step 1: Confirm the oscillator domain (MCU clock vs RTC) and target frequency.

Step 2: Check the MCU or RTC oscillator requirements in the datasheet (recommended ESR range, CL, drive level guidance).

Step 3: Choose the package based on available PCB area and margin needs (3225 for stability, 2016 for compact designs, 3215 for 32.768 kHz RTC only).

Step 4: Validate CL implementation on PCB and keep routing short and symmetric, with a clean ground reference.

Step 5: Verify startup and frequency behavior on real boards across temperature and supply conditions.

5. External references for design validation (non-competitive)

For teams standardizing their validation method, these references are commonly used:

• NIST Frequency Standard (time and frequency reference):

NIST Time & Frequency Division

• Microchip oscillator basics and crystal guidance (application notes and design tips):

Microchip Documentation Portal

• ST RTC/LSE design guidance (RTC oscillator considerations):

STMicroelectronics Documentation Portal

Video reference: SMD quartz crystal packages and applications

Review SMD quartz crystal options for MCU clocks and RTC timekeeping. Contact Suntan for selection guidance, availability, and quotation requests.

Always verify final oscillator requirements and constraints using the MCU/RTC datasheet and the crystal datasheet.