Engineers searching for polymer aluminum electrolytic capacitors for modern power supply designs typically evaluate three practical priorities: low ESR for stable output filtering, high ripple current capability, and predictable sourcing for build schedules. As power density increases, these priorities become harder to balance when board area, thermal headroom, and BOM cost are all under pressure.

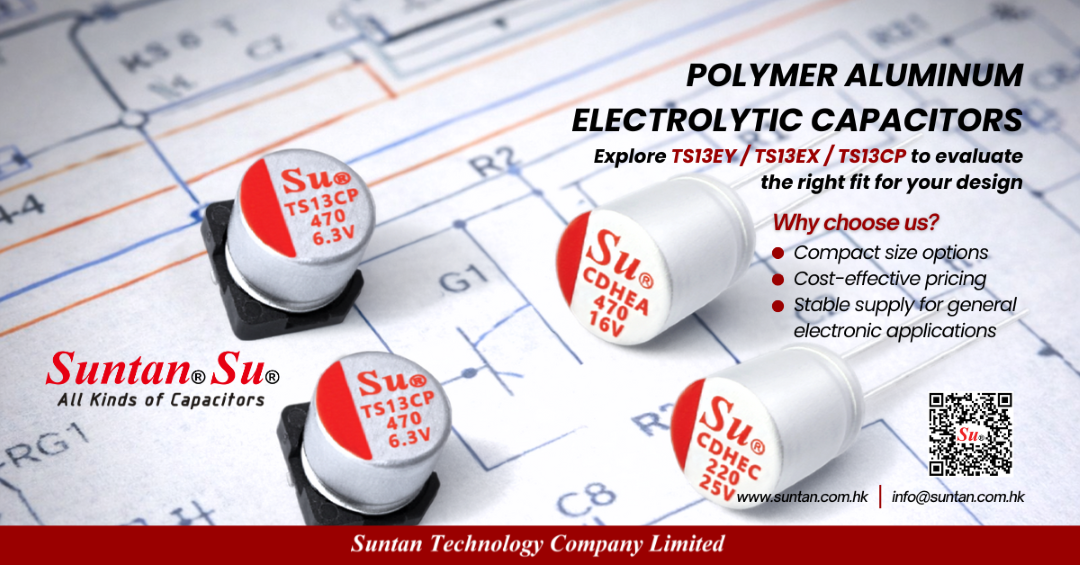

The Suntan TS13 polymer capacitor series is positioned for designers who need a compact, design-friendly, and cost-effective polymer solution for DC-DC converters, power rail decoupling, and power supply output filtering without forcing a premium-only sourcing decision.

This guide explains why polymer capacitors matter in compact power electronics, how TS13 fits typical power design constraints, and how to select between TS13CP, TS13EY, and TS13EX.

1. Why Polymer Aluminum Electrolytic Capacitors Matter in Compact Power Supplies

In compact power electronics, layout constraints often become more limiting than electrical margin. Designers working on compact SMPS, DC-DC converter modules, and high-density PCBs typically need capacitors that can handle ripple currents and switching noise while keeping impedance low across operating conditions.

Polymer aluminum electrolytic capacitors are frequently selected because they can provide:

• Low ESR for improved output stability and reduced ripple voltage

• High ripple current capability to support switching loads

• Stable filtering behavior for power rails under load variation

• Compact form factors suitable for dense layouts

2. Design & Sourcing Challenges in High-Density Power Circuits

As systems move toward higher power density, engineers frequently face:

• Limited PCB area for bulk and output capacitors

• Thermal constraints near switching MOSFETs and regulators

• The need for stable performance across load transients

• Pressure to control BOM cost without sacrificing reliability

Traditional aluminum electrolytics may struggle to meet ESR or ripple requirements in compact layouts, while some premium polymer options can introduce cost and sourcing risk during ramp-up or requalification. TS13 is designed as a balanced option for design-in practicality and procurement stability.

3. TS13 Polymer Series Overview (CP / EY / EX)

The TS13 family is organized into three models to cover common compact power design environments: SMD high-density layouts, low ESR filtering, and high-temperature margins.

4. How to Choose the Right TS13 Model (Engineering-Oriented)

Use the decision logic below to reduce selection time during design-in:

• Choose TS13CP when your primary constraint is board space and you need a compact SMD polymer solution.

• Choose TS13EY when your priority is low ESR output filtering and stable power rails in DC-DC and conversion stages.

• Choose TS13EX when your design faces higher ambient temperatures or proximity to heat-generating components and you need extra thermal margin.

5. Practical Benefits for Procurement: MOQ, Lead Time, and Production Stability

Beyond electrical performance, a polymer capacitor selection often impacts sourcing risk. TS13 is positioned to support smoother transitions from evaluation to production by focusing on:

• Stable availability planning for prototype and production phases

• MOQ-friendly sourcing for design validation and pilot builds

• Competitive cost structure suitable for volume production

For OEMs and distributors, this reduces schedule risk and lowers total BOM volatility during ramp-up.

Recommended Video: TS13 Polymer Overview

Review TS13 polymer series options for compact power design, filtering, and high-temperature environments. Contact Suntan for pricing, availability, and design-in inquiries.

Always refer to the official Suntan datasheets for detailed ratings, safety notes, and design limits.