For power electronics engineers, procurement teams, and high-reliability design projects. High-voltage polypropylene (PP) film capacitors are a cornerstone in modern power supplies, welders, motor drives, EV chargers, and industrial control boards. If you're sourcing reliable box-type capacitors in the 250–2000 VDC class, the Suntan TS09Q series offers electrically stable PP film, low loss characteristics, and wide operating range — all backed by IEC-compliant performance.

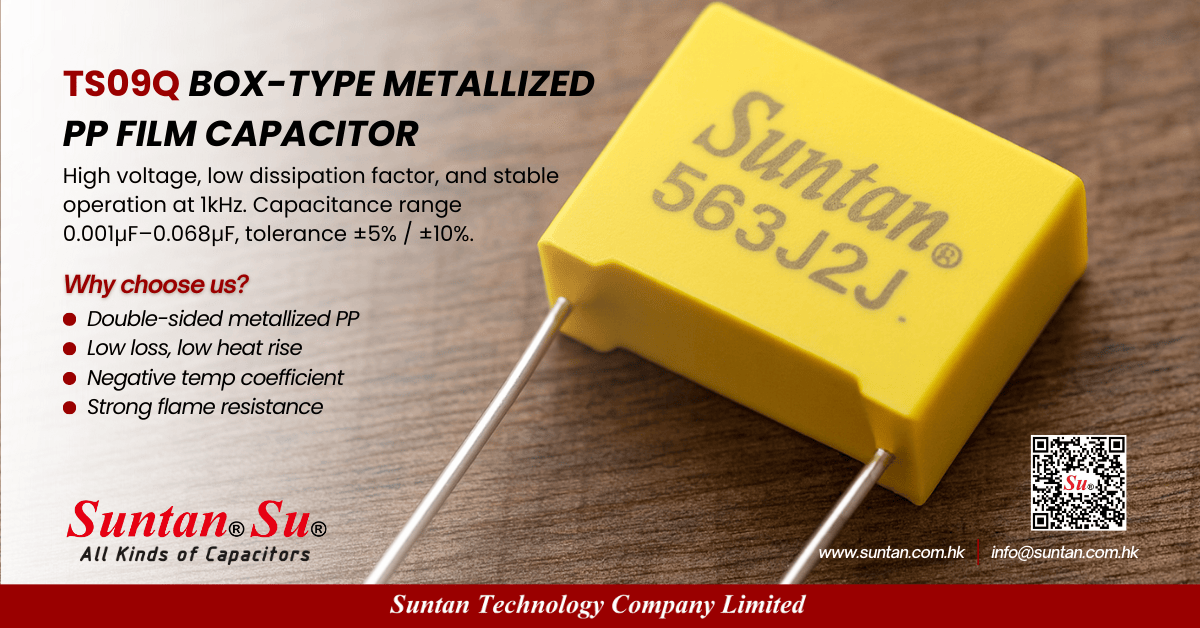

TS09Q Product Preview

Below is a visual overview of the Suntan TS09Q series. The image highlights its double-sided metallized polypropylene construction and high-voltage capability, suitable for power supplies, snubber networks, and industrial HV designs.

1. Why PP Film Capacitors Are Preferred in High-Voltage Designs

Polypropylene (PP) film is widely used in high-voltage circuits due to its low dielectric loss, high insulation resistance, and stable temperature behavior, as defined in IEC 60384-1 and IEEE capacitor standards.

These material properties make PP film suitable for EMI suppression, snubber networks, high-frequency PWM stages, resonant converters, and energy discharge applications.

Key electrical advantages of metallized PP film:

• Extremely low dissipation factor (tanδ ≤ 0.001 @ 1 kHz)

• Natural self-healing behavior

• Negative temperature coefficient for capacitance stability

• High insulation resistance for long-term reliability

2. TS09Q Electrical Specifications

Electrical ratings (from official datasheet):

• Reference Standard: GB/T14579 (IEC 60384-17)

• Operating Temperature: −40 °C to +85 °C

• Rated Voltages: 630 VDC, 1600 VDC, 2000 VDC

• Capacitance Range: 0.001 µF to 0.068 µF @ 1 kHz

• Tolerance: ±5 % (J), ±10 % (K)

• Dissipation Factor: tanδ ≤ 0.001 @ 1 kHz

Insulation resistance & dielectric strength:

• C ≤ 0.33 µF → ≥ 50,000 MΩ

• C > 0.33 µF → ≥ 15,000 MΩ·µF

• Voltage Proof: 1.6 × UR for 5 s

• Construction: double-sided metallized polypropylene film

These characteristics match IEC 60384-17 requirements for fixed PP film capacitors and support use in snubber networks, resonant converters, industrial SMPS, and capacitor discharge ignition (CDI) systems.

3. Mechanical Range & Dimensions

Voltage & mechanical portfolio:

TS09Q covers multiple voltage classes from 250 VDC to 2000 VDC, with detailed mechanical variants listed across datasheet pages 1–5.

Typical size window:

• Width (W): 10–32 mm

• Height (H): 9–33 mm

• Thickness (T): 4–18 mm

• Pitch (P): 7.5–27.5 mm

• Lead Diameter (d): 0.6–0.8 mm

This mechanical breadth makes TS09Q suitable for both compact power modules and larger high-voltage topologies.

4. Typical Applications

Where TS09Q is typically used:

• High-voltage SMPS — low loss and high insulation enable stable PWM, LLC resonant, and PFC operation.

• Snubber capacitors for IGBT / MOSFET — PP film supports high dv/dt and fast switching edges.

• Industrial controls & motor drives — −40 °C to +85 °C range fits industrial automation environments.

• Pulse discharge & energy storage — self-healing film supports repetitive high-stress cycles.

• High-voltage AC circuits — includes variants up to 700 VAC (see datasheet page 5).

5. Why Distributors and Procurement Teams Choose TS09Q

Commercial & sourcing advantages:

• Wide voltage and capacitance range: 250 VDC to 2000 VDC, 0.001–0.068 µF.

• Stable supply chain for industrial procurement cycles.

• Meets IEC 60384-17 requirements while offering strong commercial flexibility.

• Flame-resistant design with “excellent active and passive flame resistant abilities” stated in the datasheet.

6. External Technical References

Non-competitor technical references often used by engineers:

• IEC 60384-17 — fixed polypropylene film capacitors

• IEC 61071 — power capacitors for high-voltage applications

• IEEE Std 18 — power capacitor performance

• NASA EEE-Parts Guidelines — metallized film capacitor reliability

• Wiley publications on PP film capacitors under high-voltage stress

7. Recommended Video for Engineers

Engineering & Procurement Contact

Access full technical files and get engineering support directly from Suntan for your next high-voltage capacitor design.

Always refer to the official Suntan datasheets for detailed ratings, safety notes, and design limits.